Nuclear Fusion

- Introduction to Nuclear Fusion

- Physics of Nuclear Fusion

- Energy from Nuclear Fusion

- Fusion Reactors

- Confinement and Heating

- Fusion Reactor Design

- Radiation and Safety

- Fusion Reactor Materials

- Fusion and the Environment

- Challenges in Nuclear Fusion

- The Future of Nuclear Fusion

Fusion Reactor Materials

Material Selection for Fusion Reactors

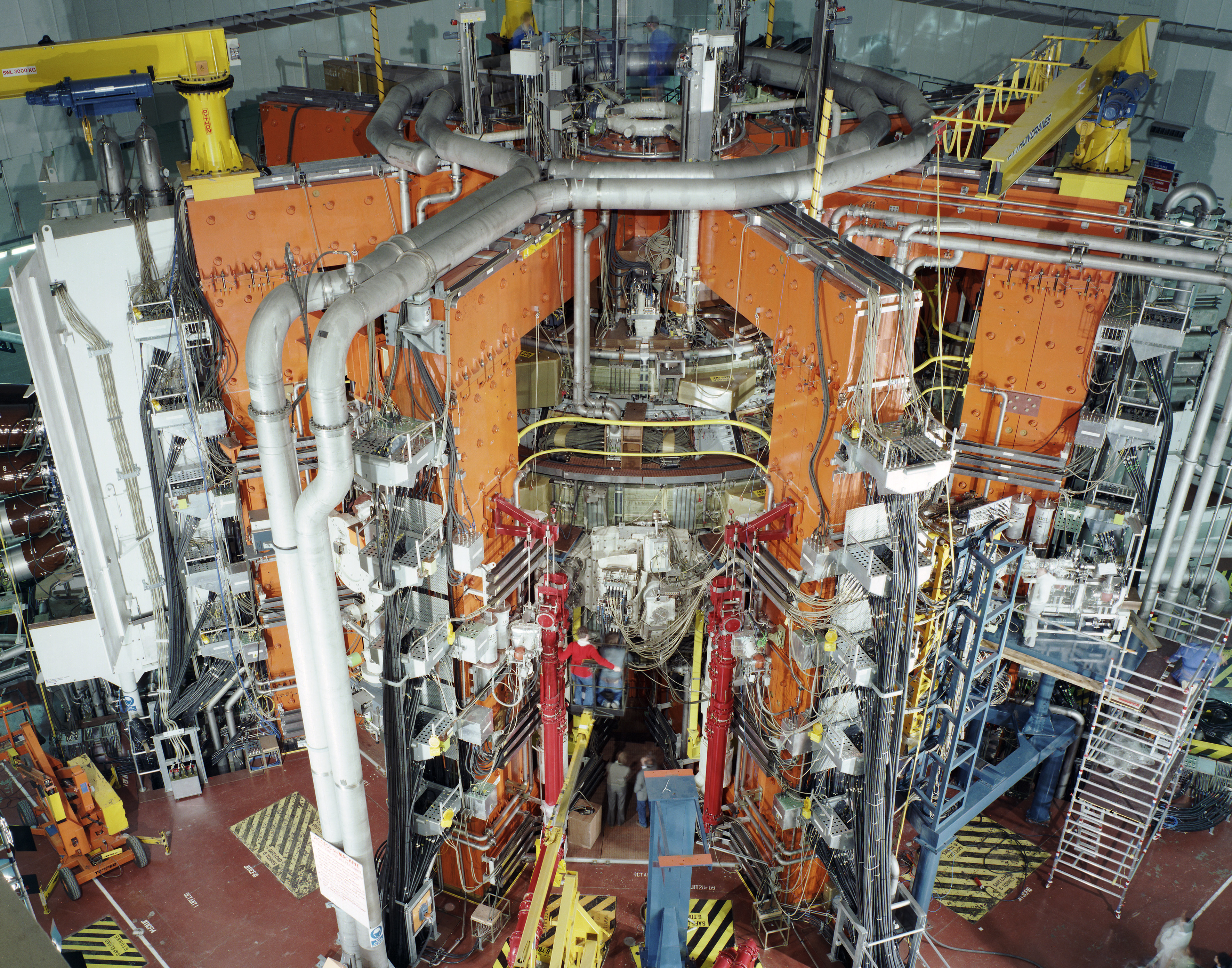

Experimental type of electricity generation using nuclear fusion.

The selection of materials for fusion reactors is a critical aspect of reactor design and operation. The materials used must withstand extreme conditions, including high temperatures, intense radiation, and mechanical stress. This unit will delve into the criteria for material selection, how materials perform under these conditions, case studies of material selection in existing fusion reactors, and future trends in this area.

Criteria for Material Selection

The primary criteria for material selection in fusion reactors include:

- Thermal Resistance: The materials must withstand the high temperatures generated by the fusion reactions.

- Radiation Resistance: The materials must resist damage from the intense neutron radiation produced in the reactor.

- Mechanical Strength: The materials must maintain their structural integrity under the mechanical stresses experienced in the reactor.

- Compatibility with Coolants: The materials must not react adversely with the coolants used in the reactor.

- Low Activation: The materials should not become highly radioactive after exposure to neutron radiation.

Material Performance Under Extreme Conditions

Different materials exhibit varying degrees of performance under the extreme conditions in a fusion reactor. For instance, tungsten and beryllium are often used as plasma-facing materials due to their high melting points and low sputtering yields. However, these materials can suffer from issues such as blistering and erosion under the intense conditions in the reactor.

Case Studies of Material Selection

Several fusion reactors provide case studies of material selection. For example, in the ITER reactor, a combination of beryllium, tungsten, and stainless steel is used. Beryllium is used for the first wall of the reactor due to its low atomic number and good thermal properties. Tungsten is used for the divertor due to its high melting point and low sputtering yield. Stainless steel is used for the vacuum vessel and other structural components due to its good mechanical properties and relatively low cost.

Future Trends in Material Selection

Future trends in material selection for fusion reactors include the development of advanced materials with improved properties. For example, research is being conducted into the use of high-temperature superconductors for the magnetic coils, which could significantly improve the efficiency of the reactor. Additionally, research is ongoing into materials with improved radiation resistance, such as silicon carbide composites.

In conclusion, the selection of materials for fusion reactors is a complex task that requires a careful balance of various factors. As research progresses, we can expect to see the development of new materials that will further enhance the performance and efficiency of fusion reactors.